Mastering the Food Slicer: Best Practices for Consistent Cuts

A commercial food slicer can transform how your kitchen handles prep – saving time, reducing waste, and elevating consistency. But only if it’s used correctly. From perfecting cut thickness to preventing accidents and maintaining blade sharpness, there’s a lot more to using a food slicer than flipping the switch.

Whether you’re new to commercial slicers or want to refine your team’s technique, this guide covers everything you need to know about using and maintaining your food slicer for reliable, high-quality results.

How to Use a Commercial Food Slicer for Precision Cutting

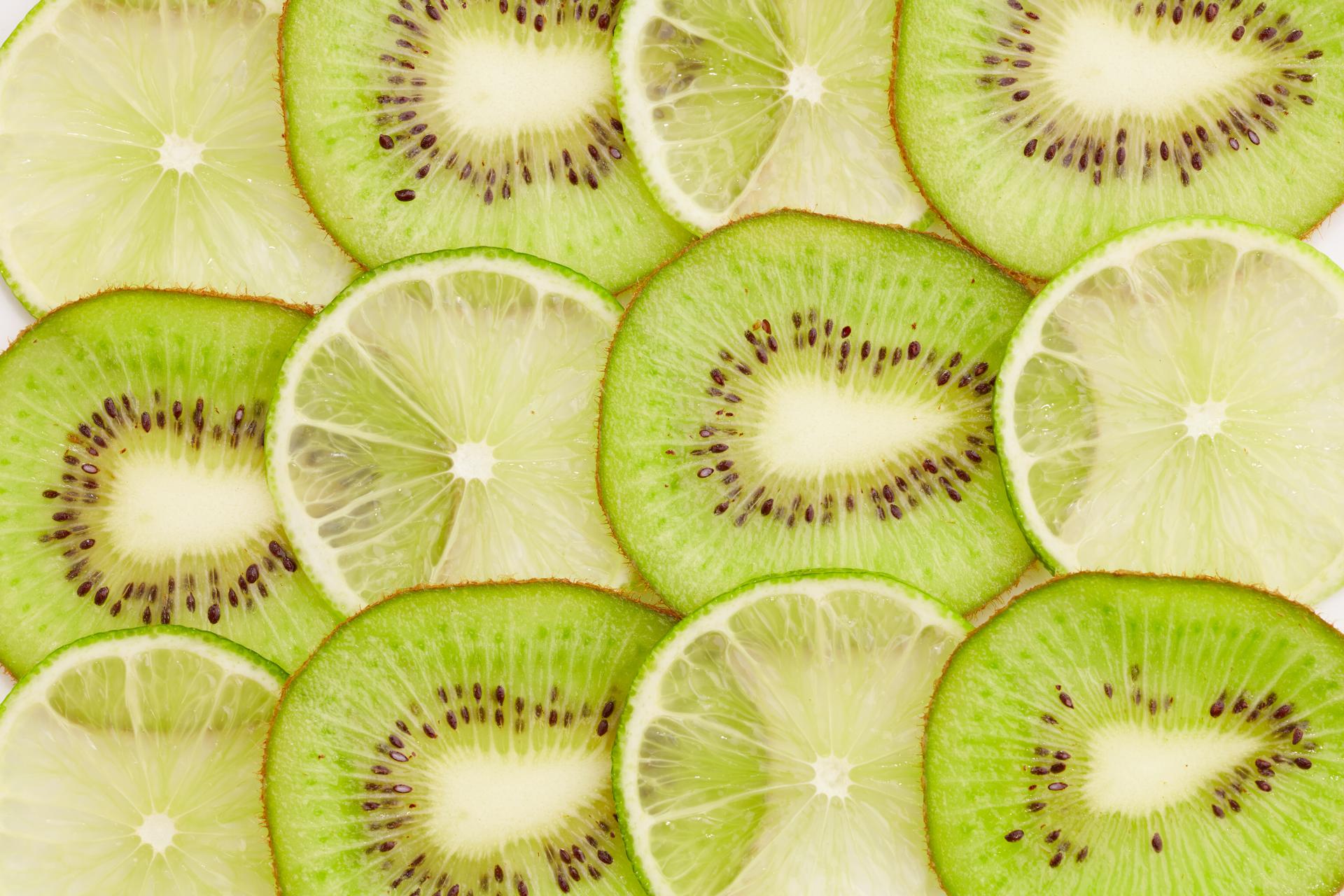

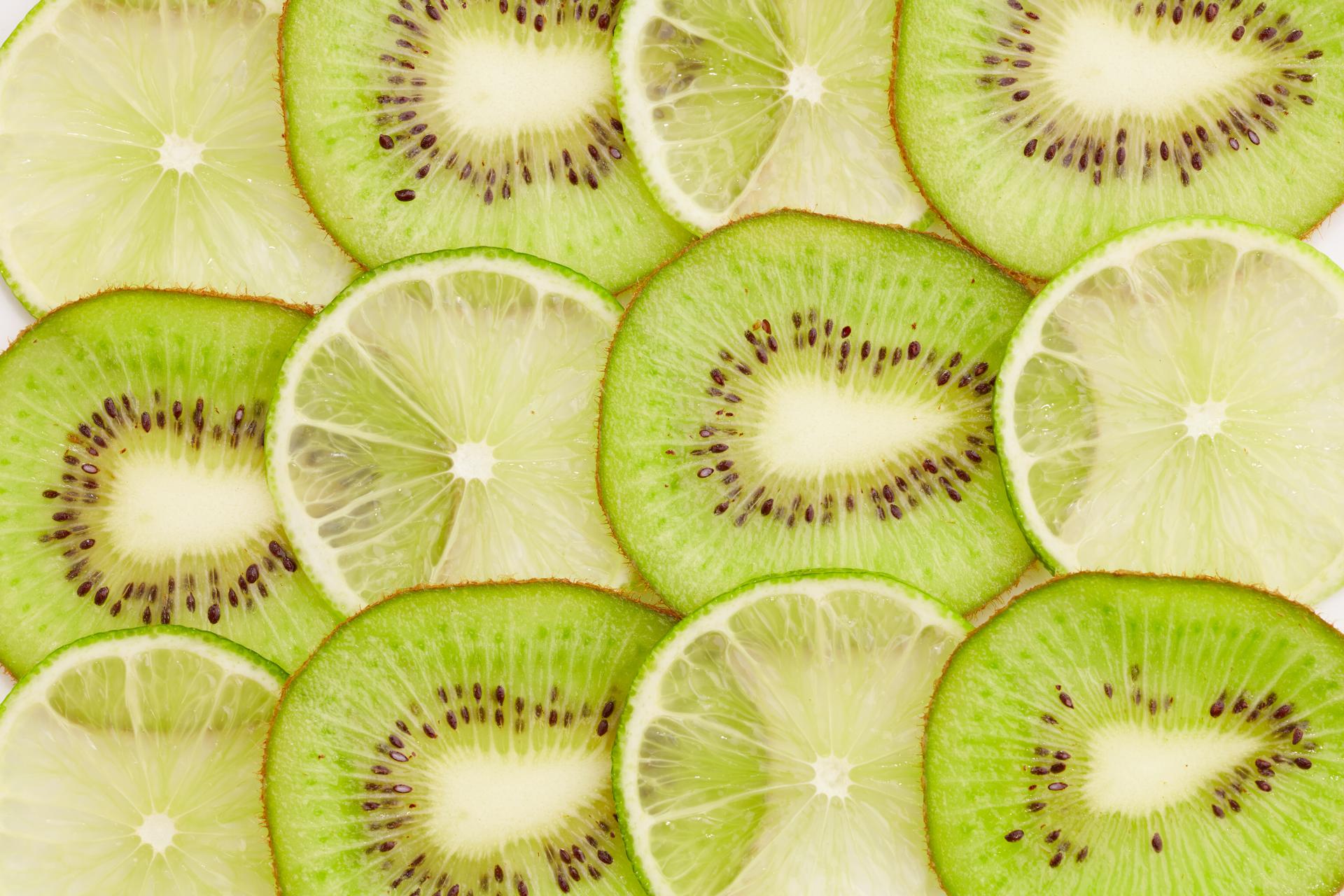

Commercial food slicers are designed to deliver precise, repeatable slices – ideal for everything from cured meats to firm vegetables. But to unlock their full potential, it’s important to treat the slicer as a precision instrument, not just another machine on the line.

Before you begin, always start with a stable, sanitized workspace. Assemble the slicer carefully, ensuring that the blade and guard are properly fitted. Many high-quality vegetable slicers and cutters, including Dito Sama models, are equipped with safety interlock systems that prevent the machine from operating unless all components are securely in place.

Next, adjust the thickness dial thoughtfully – consider the ingredient, the intended texture, and the visual appeal of the final dish. For example, paper-thin slices are perfect for carpaccio or garnishes, while thicker cuts may be preferred for roasting or layering in sandwiches.

When feeding food through the slicer, always use the food pusher and apply steady, consistent pressure. Jerky or uneven motions can result in ragged cuts and increase the risk of injury. Let the blade do the work – high-quality slicers are designed to glide through product with minimal effort.

Working in organized batches can also streamline your prep. Group ingredients by slicing thickness or recipe use, so you’re not constantly resetting the machine or switching out discs. This saves time and minimizes handling, which improves hygiene and reduces the chance of cross-contamination.

Don’t forget to keep your workspace organized: have trays ready to collect sliced product, and clean as you go. A cluttered slicing station can slow you down and create unnecessary risks.

With proper technique, a food slicer can transform prep from a time-consuming chore into a clean, efficient process that enhances every dish on the menu.

Common Mistakes to Avoid When Operating a Food Slicer

Even experienced kitchen staff can develop habits that reduce the effectiveness of commercial slicers – or worse, put safety at risk. Here are a few pitfalls to avoid:

- Skipping setup checks: loose blades or misaligned parts can affect performance and safety.

- Applying uneven pressure: forcing the food through the slicer increases wear on the motor and creates irregular cuts.

- Using dull blades: a dull blade not only reduces slicing quality but also makes the machine work harder, shortening its lifespan.

- Neglecting cleaning: slicer blades and food trays should be cleaned thoroughly after each use to prevent contamination and buildup.

- Cutting unsuitable items: not all foods belong in a slicer. Avoid slicing very soft, crumbly, or frozen items unless the machine is rated for it.

Training your staff to recognize and avoid these issues will help extend your slicer’s lifespan and keep operations smooth.

Cleaning and Maintenance Tips for Long-Lasting Performance

A well-maintained slicer performs better, lasts longer, and keeps your kitchen compliant with health codes. Here’s how to keep it in peak condition:

01.

Disassemble and clean daily:

wipe down all surfaces, remove food particles from hard-to-reach areas, and sanitize according to your kitchen’s standards.

02.

Sharpen the blade regularly:

most slicers come with a built-in sharpening tool. Follow the manufacturer’s guidelines for frequency and technique.

03.

Inspect seals and moving parts:

look for signs of wear or damage and replace parts proactively to avoid downtime.

04.

Lubricate according to the manual:

if required, apply food-safe lubricant to moving parts as directed.

05.

Store safely:

when not in use, unplug and cover the slicer to protect it from dust and debris.

01.

Disassemble and clean daily:

wipe down all surfaces, remove food particles from hard-to-reach areas, and sanitize according to your kitchen’s standards.

02.

Sharpen the blade regularly:

most slicers come with a built-in sharpening tool. Follow the manufacturer’s guidelines for frequency and technique.

03.

Inspect seals and moving parts:

look for signs of wear or damage and replace parts proactively to avoid downtime.

04.

Lubricate according to the manual:

if required, apply food-safe lubricant to moving parts as directed.

05.

Store safely:

when not in use, unplug and cover the slicer to protect it from dust and debris.

Many Dito Sama models are designed for easy disassembly and hygiene, helping streamline cleaning without sacrificing durability or performance.

With the right habits and tools, a commercial food slicer becomes more than just a prep tool – it becomes an essential part of a faster, safer, and more consistent kitchen operation.

LAST NEWS